Nobody enjoys taking a physical count of inventory. It is, however, unavoidable and vital for your business. Knowing exactly what you have on the record and what is actually in stock will be very beneficial. It ensures accuracy and can uncover the reasons for running out of stock early. It also helps businesses to have exactly what they need in stock at all times.

This article created by our team at Pack4it explains what a physical count of inventory is and provides tips on how to do it best.

Physical Inventory Count – What Is It?

A physical inventory count refers to the counting of all the products in stock in person. This means that an employee (or a team) must count every item that is present in the store and warehouse. Employees can use a pen and paper or an electronic method to record the information.

This count ensures that there are no inaccuracies or discrepancies in stock levels. The physical inventory items should match the quantities recorded in the inventory books (or management software).

If a discrepancy occurs, update the inventory record to reflect the physical quantity. Taking a physical inventory count is a requirement of the federal tax law.

This ensures that businesses do not oversell, and they don’t keep too much inventory in stock. Also, it is beneficial to get the correct inventory valuation for your tax returns.

With all the above in mind, it is vital to conduct a physical inventory count with care. Accuracy will prevent any negative upshots. For example, exaggerating the physical count of inventory increases the gross and net profits. This results in a higher income tax charge.

To assist you with this necessary process, here are some useful tips for planning and executing the physical inventory count.

Before And During a Physical Inventory Count

After deciding on the method of carrying out the count, it’s necessary to prepare for and implement it. Follow the steps below to help ensure the accuracy of the count.

Obtain Needed Supplies

Some businesses use inventory software to print out barcode labels. Others may use inventory tags. These tags indicate which items have been counted and how many times. Ensure there are enough paper, pencils, and pens available. Provide clipboards to make writing more comfortable and efficient. Think about the accessibility of items and, where necessary, provide step stools, ladders, masks, and gloves.

Pick the Counters

Do not choose random employees to count the inventory. Although it may seem like an easy job, counting is subject to errors. You can select both new and experienced employees. However, always select those who are focused and diligent.

Notify All Storage Sites

Counting stock held at external locations or on shipload is also necessary. It is best to carry out a physical inventory count on the same date, across all locations.

Inspect the Shelf Tags

Ensure that all the products on each shelf harmonize with the description on the tag. Employees may assume that the tags are correct, without double-checking. Conducting a visual inspection will prevent any potential discrepancies.

Halt Warehouse Activities

Make sure to put aside the recently delivered merchandise. To avoid confusion and prevent mistakes, cancel any deliveries for the time of the count.

Map Out the Area

Remember that each item of your inventory must be counted. Pay attention to details. Do not miss even the smallest area, shelf, bin, or drawer. Creating a map will make it easier to conduct the count. It will also allow you to assign counters to specific areas without the fear of them doubling up on one another. The smaller the sections, the easier the count.

Group the Merchandise

Categorize all products into groups. Then organize similar categories in a logical order. This will enable the employees to count faster and with more accuracy.

Orientate the Team

Walk your team through the previous steps. Ensure they are familiar with the map and know the areas allocated to them.

If you have moved anything around or changed any labels make sure they are aware of it. Do not send them into the job unprepared. Show them around the sales floor or warehouse. Allow them time to get acquainted with it.

During the preparation, you may notice that some commodities do not belong to any specific place or category. Those include:

- products displayed in the store window

- goods transferred from other locations

- returns

Decide what to do with them in advance. Use the POS system to maximum advantage. Register categories from the POS system on the counting sheets along with the prices. Ensure the prices are correct (regular vs. sales).

Conduct a Pre-Count

You can count some items the day before the inventory count day. Put all counted goods in boxes and seal them. The following day, make sure that the seals are not broken (in which case you will have to count the items again).

Provide Refreshments

Counting one item after another for a long time is physically and mentally tiring. The counters would appreciate something quick to eat and drink during breaks. It will help them regain physical energy and mental focus.

Executing the Count

After each small section, the appointed manager needs to verify the count. It is advisable to start with the merchandise that brings in the most money and the items that move the fastest. It is important to get those done early as they are subject to more counting errors. If the manager has verified the counts, record it in the spreadsheet or management system.

After the completion of the inventory count, print out and review discrepancy reports.

Meet with the counting team to analyze the counting process and document the procedures. Ask employees what they thought worked well and what areas need improvement. Using this information, make needed adjustments for the next physical count. This will ensure it is easier and more efficient.

Data Entry

Now it is time to enter the information into the system. Your inventory software program should include the option to enter the results of the physical count. This data will then be updated with barcoding. If you used the pen and paper method to carry out the count, be diligent. Make sure all the numbers are correct when entering the information into the system.

Run a Comparison

With the new data now entered, compare it with the frozen inventory information in the system. Pay attention to both the quantity and the cost of the merchandise. Depending on system configurations, the cost comparison will be based on the average or exact cost of each piece. This comparison will show how weighty the discrepancy is.

Inventory Count Audit

It doesn’t hurt to check one more time that the count was correct. Conduct an inventory count audit as soon as possible and before updating the stock levels. Never postpone the inventory checks and audits.

Use the inventory reports to examine the information and discover how to refine your business. Finding the right report is simple. Use the ‘report generation’ option in the POS and retail management system if it’s available.

These analytics will help you to create procedures that minimize discrepancies. You can use physical inventory count reports for a certain period to spot any tendencies. You may notice that a specific area of the store tends to have a much lower physical count. This could mean that customers have been stealing from that particular area. Focusing more attention on this area can prevent further stock discrepancies.

The results of the count and the insights gained from the subsequent comparisons should inform the way the business is run.

Top 10 Tips

Here are some tips that will improve the speed, accuracy, and efficiency of a physical inventory count.

Make Plans in Advance

You must conduct a physical count of inventory every year as required by the tax law. However, it is possible to carry out counts at any time that you find appropriate. If desired, a physical inventory count may be undertaken every quarter or even every month.

Employees must receive advance notification each time. They need enough time to arrange their schedules since the count is usually conducted outside of regular work hours. If the count will occur during business hours, inform customers at least 5 days beforehand. Displaying a simple notice on the storefront can serve this purpose.

Select the Team Members Carefully

It is advisable to have a mixture of experienced and new employees in the inventory count team. The old-timers are well-acquainted with the policies, procedures, and locations. They are, however, more prone to miss smaller details. Newer employees may be paying more attention and might spot certain issues.

Work in twos

Divide the counting team into pairs and allocate a section to each pair. One employee should do the actual counting. The other person’s responsibility is to label the count tags with the appropriate data.

Make a Map

Mapping out the store floor or warehouse simplifies the inventory count procedure. Make sure that the map is clear and shows everything of relevance. This includes all walls, racks, shelves, display units, workstations and backrooms, and anything else that is relevant. Then number them to indicate which section they belong to.

Use Labels

If any items are not visible (being for example in a box), use labels to show that those goods should also be counted. Remember to mark and label everything before the inventory count is underway. Avoid wasting time dealing with loose items that weren’t counted.

Try Cycle Counting

A cycle count is an inventory procedure where a small subset of inventory, in a specific location, is counted on a specified day. Cycle counts are less disruptive to daily operations and are customizable. They can focus on merchandise with a higher value, higher movement volume, or items that are most vital to business processes.

The Ranking Method suggests you count the faster-moving items more often. The basis for this is Pareto’s Law which states that 80% of consequences come from 20% of the causes. This 80/20 rule means that 80% of your sales is provided by 20% of your stock.

Identify High-Risk Areas and Keep Loss of Inventory Down

Use inventory count reports to spot trends in discrepancies. If you notice a pattern of inventory loss in a specific area such as bins next to the entrance or where expensive goods are, talk to your employees and instruct them to keep their eyes open for thieves.

Take The Team’s Physical Needs Into Account

A physical inventory count is tiring both physically and mentally. It is also time-consuming and monotonous, even boring.

Hungry, thirsty, tired, or bored counters are prone to commit errors. For this reason, you must provide food and drinks and ensure regular breaks. Let team members rest their eyes and regain physical and mental energy.

Other Inventory Systems

The periodic inventory system is a method of inventory valuation for financial reporting purposes. In this system, a physical count of the inventory is performed at specific intervals. It is suitable for smaller businesses.

The perpetual system keeps a continuous track of inventory balance. Receipt or sale of a product is automatically updated on the POS and asset management software.

Ending thoughts on taking a physical count of inventory

Taking a physical inventory count is nobody’s favorite activity. It is time-consuming, tiring, and may even disrupt normal business operations.

The conventional method uses a pen and paper. The counters record the counts on a provided sheet and then input the results into the system. This method is slow-moving and cumbersome as it requires double data entry. The counting itself indeed needs to be done physically and there is no way around it. You do not want to have the extra job of manually summing up and recording the information.

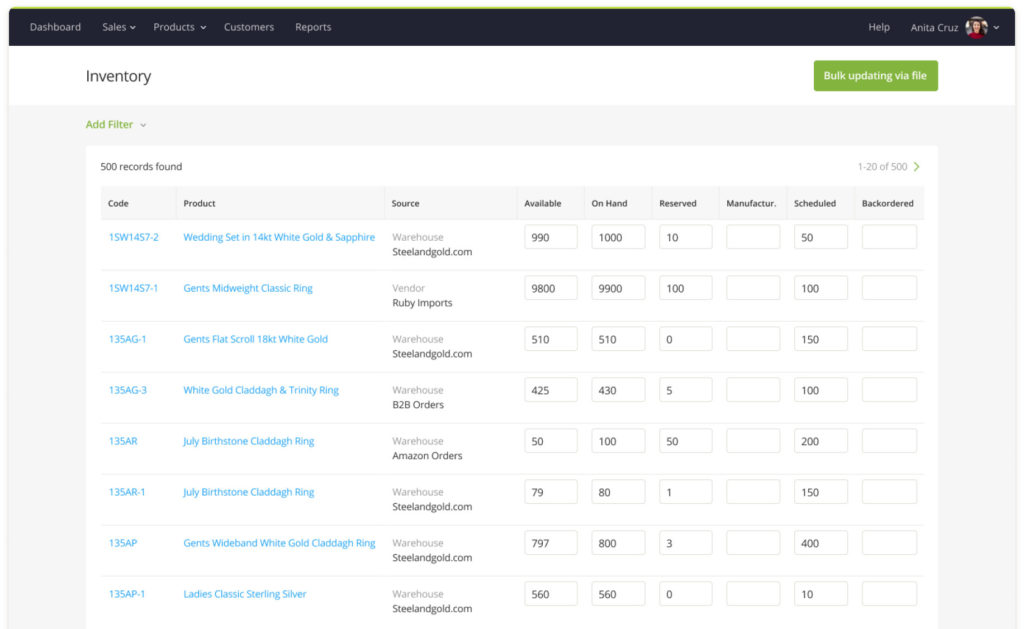

Pack4it is here to assist you. The Warehouses and Vendor Stock Management function streamlines the physical count of inventory. The barcode scan feature enables your team to use multiple devices at the same time. This helps to speed up the counting process.

If you enjoyed reading this article about taking a physical count of inventory, you should read these as well: